Search

We position ourselves as a technology leader in filtration

• Harald Spaeth, President – Heavy Duty & Industrial, Mann+Hummel • Sudeesh Karimbingal, Managing Director India & Vice President – OE RoA, Mann+Hummel

Mobil drives mining’s digital evolution with future-ready lubrication

Vasanth Thangavelu, General Manager – Brand Marketing South AP, ExxonMobil Lubricants, shared how the brand continues to strengthen its commitment to India’s mining sector through advanced lubrication solutions, digital tools, and technical services designed to help operators achieve superior reliability and performance.

Mobil drives mining’s digital evolution with future-ready lubrication

Vasanth Thangavelu, General Manager – Brand Marketing South AP, ExxonMobil Lubricants, shared how the brand continues to strengthen its commitment to India’s mining sector through advanced lubrication solutions, digital tools, and technical services designed to help operators achieve superior reliability and performance.

CCI clears Allison Transmission’s Rs 16k-cr acquisition of Dana’s off-highway unit

Competition Commission approves Allison’s purchase of Dana Incorporated’s off-highway business.

Allison to Acquire Dana Inc.'s Off-Highway Business in New Agreement

Allison will be able to offer a wider range of commercial-duty powertrain and industrial solutions

Caterpillar Powers Today and Drives Tomorrow at bauma 2025

Celebrating Caterpillar’s Centennial and ‘The Next 100 Years’.

TSF Group Highlights Make in India Focus at Bharat Mobility

TSF Group showcased its strength in domestically developed automotive technology

Lubricants play a crucial role in equipment efficiency: V. Maloo, ENSO

Vaibhav Maloo, Managing Director, ENSO Group, speaks on the primary factors that construction equipment customers prioritise when selecting lubricants.

Our focus has expanded to encompass complete oil life cycle management: Praveen Nagpal, Shell

Praveen Nagpal, Chief Technology Officer, Shell Lubricants India, discusses the primary factors that construction equipment customers prioritise while selecting lubricants.

Focussing towards more sustainable offerings for the construction industry

Jayanta Ray, General Manager – Industrial and OEM, GS Caltex India, speaks on the primary factors that construction equipment customers prioritise when selecting lubricants.

Powering Progress

The article explores the reasons behind the increasing usage of diesel engines in construction equipment, their impact on performance and efficiency, and the technological advancements shaping the future of construction machinery.

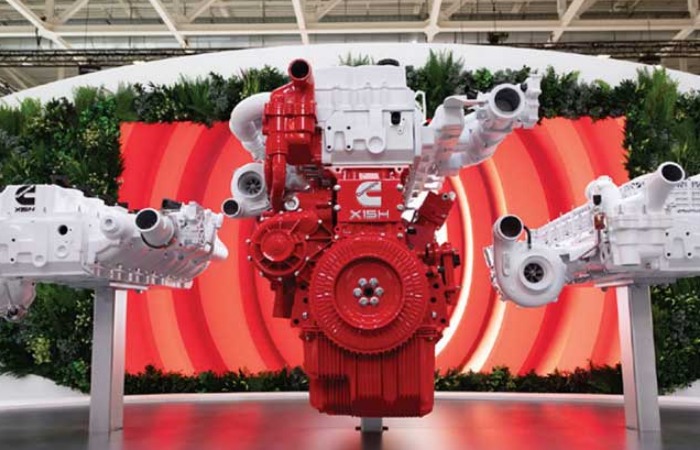

India is a critical market for Cummins

Antonio Leitao, Vice President – Off Highway, Engine Business & Europe ABO Leader, Cummins Belgium, speaks on the company’s product lineup and the salient features of these engines.

India is a critical market for Cummins

Antonio Leitao, Vice President – Off Highway, Engine Business & Europe ABO Leader, Cummins Belgium

EXCON 2023 Day 2 Highlights

EXCON day 2 highlights, Bangalore

Caterpillar Unveils High-Performance C13D Engine in India

Caterpillar introduces C13D engine at Excon 2023

CAT to develop hydrogen-hybrid solution for off-highway vehicles

Caterpillar announced the launch of a three-year programme to demonstrate an advanced hydrogen-hybrid power solution built on its new Cat® C13D engine platform.

CAT to develop hydrogen-hybrid solution for off-highway vehicles

The project will leverage the versatile new Cat® C13D engine platform.

Terex’s Concrete Mixers with Hydrogen Engine

In a groundbreaking move, Terex is poised to offer Cummins' X15H hydrogen internal combustion engine as an alternative for its Terex Advance Commander Series of front-discharge concrete mixer trucks.

Tata Motors, Cummins collab for low- to zero-emissions technologies

Global power leader, Cummins Inc announced that it has signed a definitive agreement with Tata Motors (TML) to manufacture a range of low- to zero-emissions technology products in India over the next few years.

Cummins, Tata Motors collab to power a cleaner India with low- to zero-emissions technologies

Cummins Inc. and Tata Motors strengthen their 30- year alliance to power a cleaner India with low- to zero-emissions technologies for mobility solutions

Cummins showcases 15L fuel-agnostic engine platform

At CONEXPO, Cummins showcased its new fuel-agnostic 15-liter engine platform with hydrogen, natural gas and advanced diesel engines offering low-to-zero carbon fuel capability.

Caterpillar unveils 13-litre engine platform for heavy duty off-highway applications

The Cat C13D engine platform has been engineered to deliver the performance, durability, packaging, and ease of maintenance demanded by both manufacturers and buyers of off-highway equipment.

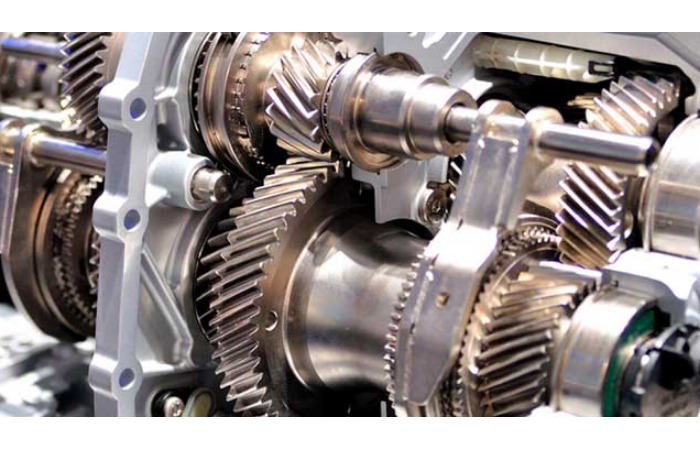

Efficiency Drives Transmission Developments

The transmission system plays a vital role in equipment as the gearbox determines the performance and robustness of the equipment.

Sany and Danfoss introduce electric telescopic crawler crane

Sany has partnered with Danfoss to introduce an electric telescopic boom crawler crane, the SCE800TB-EV. It is the first volume model of crawler crane available on the market with a fully electric system featuring permanent magnetic synchronous motor technology, the company says.

A powerful transmission

Transmission, a key component in a construction equipment vehicle, plays a major role to the functionality of the vehicle, especially in the high frequency and heavy application.

Are IoT & AI just a hype

The internet of things is significantly transforming industries such as automotive, Healthcare & Medical, Energy and Off highway.

Rolls-Royce’s MTU Aiken plant completes 10 years

The facility began with the assembly of MTU Series 2000 and Series 4000 diesel engines

GALLOCK® - complete safety under heavy vibrations

Gala Precision Engineering announced the successful development and distribution of wedge lock washer GALLOCK®. These washers are used to safely secure bolted joints exposed to heavy vibrations and dynamic load.

Engineering Growth

The growth prospects of off-highway diesel engines market is obvious in the coming years as the infrastructure equipment will play a major role in the infrastructure creation in the country.

On revival Path

In spite of the current slowdown, tyre market for off-highway applications is going to revive in the coming years due to an anticipated pick up in infrastructure developments in future.

We aim to grab 25 per cent market share in five years

ATG has wide range of radial OTR tyres for loaders, graders, dumpers etc and we see a very good response from the market. Harinder Singh, President - APAC, Alliance Tire Group (ATG), elaborates on the market scenario and company's plans.

GS Caltex showcases lube solutions

GS Caltex India showcased its Research and Development (R&D) capabilities, which is its core strength in developing product competitiveness for lubricants and polymers.

We are developing full electric drives and hybrid solutions

We are observing shift to higher power diesel engine for more productivity. We see more demand for higher power diesel engines in future.

JCB ecoMAX engine

In 2011, JCB India inaugurated a world-class engine manufacturing facility in Delhi-NCR which is also the world's largest backhoe plant. In over six years, JCB has manufactured over 1,50,000 ecoMAX engines and machines fitted with these engines have been exported to over 90 countries.

A diversified industrial major

Balkrishna Industries (BKT), has over 30 years of global presence in the off-highway tyres (OTRs)segment.

Electric Throttle Actuators

The latest electric throttle actuators provide a cost effective way to control engine speed on mechanical diesel engines. Compact and easily installed, they enable greater freedom of machine design and the use of more ergonomically optimised controls.

Green, Greener, Greenest

At a time when the government is focusing on the next level of emission compliance in on-road and off-road vehicles, EQUIPMENT INDIA explores how the market is getting ready to comply with the latest norms.

AxleTech builds first axle in India facility

AxleTech International produced the first axle from its new dedicated manufacturing facility in India. The 45,000 sq ft (4,180 sq m) plant, located in Pune, represents AxleTech?s first greenfield project in the country.

Impressive Showcase by CASH Industry

Excon 2015, in CASH domain, witnessed a plethora of equipment aggregates, sub- assemblies, components and IT solutions for OEMs in their equipment, as original suppliers and in the aftermarket space, descending on the scene of action.

backhoe loaders:flat Growth

Backhoe loaders are passing through a challenging time for the past few years. Market is registering a flat growth with some indications that it is shrinking.However, now there is optimism among the leading players in the backhoe industry

Engines of Future

Latest environmental norms, best fuel efficiency and low OPEX costs, dictate developments of new generation engines. Latest environmental norms, best fuel efficiency and low OPEX costs, dictate developments of new generation engines.

A Dynamic Show

The six-day Intermat Paris 2015 show was truly dynamic and a stepping stone in the growth path of the industry in the coming years. A report. The 10th Intermat show held on April 20-25, 2015

Gaining Momentum

A renewed thrust on coal mining, coupled with plans to implement more projects in various infrastructure segments at a faster pace has rekindled the growth prospects of tyre industry in India. Major tyre manufacturers are busy introducing innovative products and scaling up volume to meet the expected demand in the future.

Bearings for Smooth and Durable Functioning

Not as interesting or inspiring as a tiny transistor in an electronic circuit, a bearing is as important as a transistor when it comes to the smooth functioning of a machine.

Achieving Cost Efficiency

Cost efficiency is not only achieved through cleaner engines, but also through optimising the man-machine interface with a variety of machine control technologies, 'correcting' the usage patterns, and packaging solutions that take care of clients' business needs around project costs.

Oerlikon Fairfield to Launch Hybrid Electric Drivetrain

The new driveline system to be launched during the ConExpo is a complete series electric driveline system from engine to wheel featuring an innovative energy recovery system. Oerlikon Fairfield will unveil its new patent-pending hybrid electric drivetrain technology at the upcoming ConExpo-Con/Agg trade show from 4-8 March at the Las Vegas Convention Center. This technology is a complete series electric driveline system from engine to wheel featuring an innovative energy recovery system.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com